Is bamboo a good material for making toilet paper, and how is it processed?

Yes. Bamboo is a fast-growing, renewable resource with fiber properties similar to softwood. Through modern, chlorine-free pulping and bleaching technologies, it can be turned into high-quality, eco-friendly toilet paper.

Why Bamboo Is Ideal for Making Tissue Paper

Bamboo fibers are structurally similar to softwood (conifer) fibers, which are known for their strength and papermaking qualities. With a high cellulose content and medium fiber length, bamboo strikes the perfect balance between strength and softness. As a fast-growing, renewable resource, it doesn’t occupy farmland or forestland — making it an ideal raw material for sustainable tissue production.

Advancements in pulp and bleaching technology, including continuous cooking and chlorine-free bleaching (like ECF and hydrogen peroxide), have also solved previous issues related to brightness and fiber quality. Today, bamboo pulp production meets environmental standards while offering excellent performance in tissue applications.

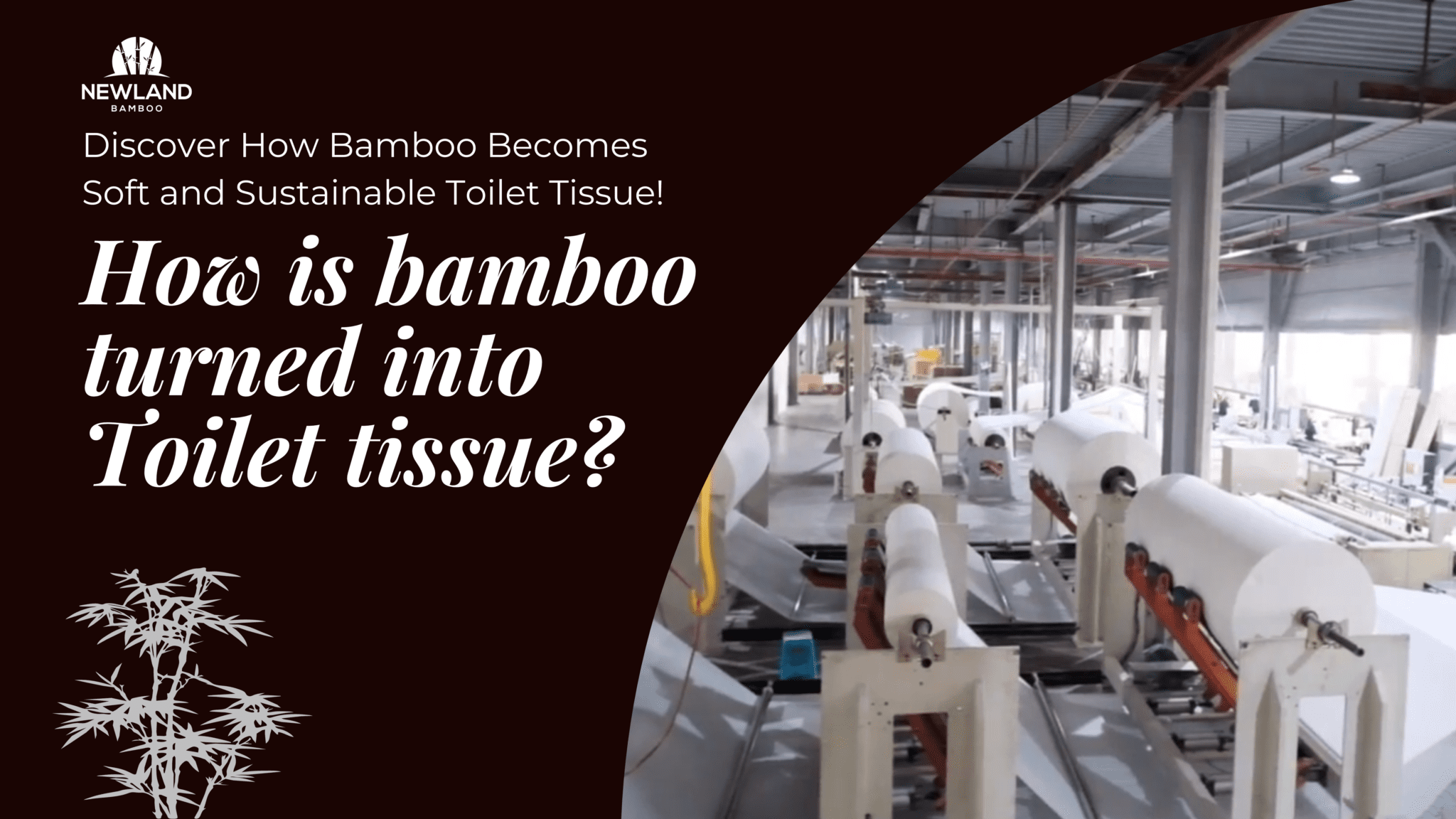

Step-by-Step: How Bamboo Becomes Toilet Paper

1. Growth & Harvest

Bamboo is one of the fastest-growing plants in the world, maturing within 3–5 years. It regenerates naturally and can be harvested multiple times a year. At Newland Bamboo, we work with bamboo forests located within 5 km of our factory to minimize transportation impact.

2. Pulping

After harvesting, bamboo stalks are chipped into small pieces. These chips are cooked under high pressure to separate the cellulose fibers from lignin and other components. The result is raw bamboo pulp — the base material for toilet paper.

3. Washing & Bleaching

The pulp goes through several washing cycles to remove residual chemicals. For bleaching, we use Elemental Chlorine Free (ECF) and hydrogen peroxide (H₂O₂) processes — both of which are safe for health and the environment, unlike traditional chlorine bleaching.

4. Pressing & Drying

Clean pulp is diluted with water and spread onto large moving screens, where most of the water is removed. The fiber mat is then pressed and dried on heated cylinders, forming thin paper sheets.

5. Reeling & Jumbo Rolls

The dry paper is softened, scraped off the dryer with blades, and wound into massive rolls called “jumbo rolls” — this is the base paper for toilet tissue.

6. Converting to Finished Rolls

Jumbo rolls are placed on converting machines, cut, rewound onto core tubes, and sliced into smaller individual rolls. These are then packed, palletized, and shipped to ports for global distribution.

Why Choose Newland Bamboo?

With over 20 years of tissue production and 10+ years in export, Newland Bamboo is a leading manufacturer of bamboo household paper products. We supply:

- 100% Bamboo Toilet Paper

- Bamboo Kitchen Towels

- Facial Tissue

- Napkins

- Paper Towels

- Pocket Tissues

- Jumbo Rolls (for OEM)

We combine eco-conscious sourcing, advanced bleaching techniques, and efficient supply chains to deliver high-quality tissue to global partners.

FAQ: Bamboo Toilet Paper Production

Looking for a reliable bamboo toilet paper supplier? Contact Newland Bamboo for OEM pricing and free samples. We deliver high-quality, sustainable tissue products to clients worldwide.

Q1: Is bamboo toilet paper really eco-friendly?

Yes. Bamboo grows quickly, requires no replanting, and doesn’t harm forests. Our chlorine-free bleaching process further reduces environmental impact.

Q2: What’s the difference between bamboo and wood pulp?

Bamboo fibers are stronger and more flexible. They also require less water and chemicals during processing.

Q3: Do you offer private labeling or OEM services?

Absolutely. We support full OEM/ODM services, including custom packaging and branding.

Q4: How long does shipping take?

For most markets, delivery takes 30–60 days depending on port and order size. Samples ship within 7 days.