Wood vs Recycled vs Bamboo Toilet Paper: A Comparison

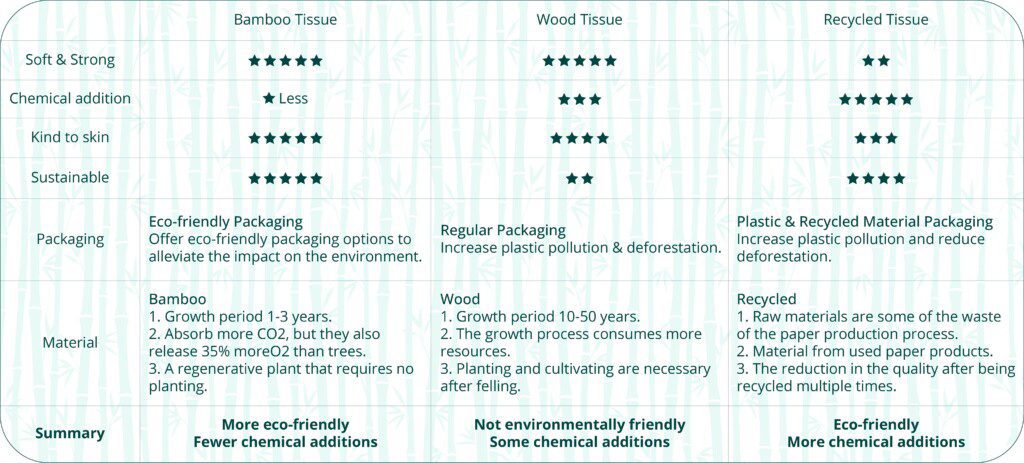

Bamboo toilet paper is a highly sustainable and eco-friendly option compared to wood and recycled toilet papers. Bamboo grows quickly, requiring less water and no pesticides, and regenerates in just a few months, unlike trees which take decades. Bamboo toilet paper is biodegradable, free from harsh chemicals, and naturally antibacterial. It is more expensive than wood pulp paper but offers superior environmental benefits. Recycled toilet paper, while environmentally friendly, may contain harmful chemicals like BPA, and its fibers weaken after multiple recycling cycles. Ultimately, bamboo is the best choice for both health and sustainability

The emergence of the novel coronavirus – brought a rise in the use of household paper worldwide. No thanks to the imposed lockdown forcing majority to stay indoors. This has brought some concerns and more focus on the papermaking industry. As more and more bamboo toilet and recycled toilet paper are flooding the market.

Also, buyers are focusing more on the health and environmental benefit of household papers. By wanting to know if they serve more purpose to the ecosystem and our health generally.

If you’re experiencing this same curiosity, this article is a detailed analysis of the differences between the (bamboo, wood, and recycled) papers from the raw material down to processing and production.

Wood Toilet Paper

1. Raw Materials

The raw materials of wood toilet paper are majorly the coniferous and hardwood that take several years (decades or centuries) to grow. However, tree growth requires a large amount of energy and water to grow due to their extensive growth period.

With this extensive growth period of trees comes a major problem – being a raw material for papermaking. Data from researchers worldwide have shown our consumption of toilet paper outwits the regeneration rate of trees. This means natural woodlands are being cut down to meet our exorbitant demands.

This is contrary to the claim of many wood pulp and toilet paper brands around the world that, their products are from sustainable commercial woodlands. Truly, the increasing demand for toilet tissue has contributed to the growth of paper industries around the world. However, it’s also contributing to the ever-degrading ecosystem balance as it is accelerating deforestation.

Wood pulp paper is a paper derived from high-quality wood by a series of processes. These include – but are not limited to – cooking and beating. Putting the requirement of producing white pulp into a more statistical perspective, a ton of white paper will require the following:

• 75 tons of wood. • 2 tons of coal. • 100-kilowatt-hours of electricity. • 300 kilograms of chemicals. • 35% of water pollution during the production process.

2. Features of Wood Tissue Paper

♦ Color Wood pulp natural is brown and requires bleaching to become the beautiful white paper we’re accustomed to. Known bleaching techniques include chlorine bleaching, elemental chlorine-free (ECF) bleaching, H2O2 bleaching, ozone bleaching, and so on.

Amongst these, chlorine bleaching is the cost-effective and most efficient option. Therefore, it is favored by many toilet paper manufacturers. However, toxic and harmful substances such as high carcinogen dioxin and adsorbable organic halogen (AOX) will be produced in the process of chlorine bleaching. To make the wood pulp appear more beautiful, some manufacturers go as far as adding fluorescent brighteners.

♦ Softness The fiber of wood pulp is delicate and soft. Consequently, papers manufactured from it inherit these properties, boast tensile strength, tear resistance, etc.

♦ Strength Wood pulp paper manufacturers usually add a small amount of wet strength agent, in order to make wood pulp paper meet customer needs. And wet strength agent is a carcinogens.

♦ Embossing and odor This isn’t a problem for wood pulp papermakers as they can easily add embossment and odor to customers. This is done during the manufacturing process.

♦ Packaging It’s no news that most wood pulp paper is packed in plastic and cartons. This makes it huge environmental pollution as those packages are non-biodegradable.

3. Transportation

Due to geographical advantages, wood raw materials, toilet paper parents roll, and finished products can usually have a closer choice. Therefore, brands can pay fewer transportation costs for nearby purchases. Of course, customers can also get their goods in a shorter time.

4. Price

Wood pulp paper has a lower cost from raw materials to processing, production, and transportation. So it has a very competitive price.

Bamboo Toilet Paper

1. Raw Materials

Bamboo is a more commercially viable raw material and the fastest-growing plant in the world. With proper planning, bamboo can be cultivated like a normal farm crop with low water consumption. To put this clearly, bamboo can grow as high as 1.5 meters in a day in the stage of development from bamboo shoots to bamboo.

Also, while it takes about 60 years to regenerate a 60-foot tree, a 60-foot bamboo can be fully regenerated in 59-days. Bamboo does not need to be planted after it is harvested and will continue to grow. Add this to the 30% fewer greenhouse gas emission by bamboo compared to wood, and you have the most environmentally friendly option amongst the paper types.

Choose bamboo toilet paper to reduce tree felling. At the same time to meet the growing needs of consumers for tissue. Compared with wood toilet paper and recycled toilet paper, bamboo tissue is more environmentally friendly. But we also need to note that the guarantee for the sustainability of bamboo sources is FSC certification.

2. Features of Bamboo Tissue Paper

♦ Color Bamboo pulp paper has natural color and white, natural color paper unbleached and not added. Newland Bamboo uses ECF bleaching and H2O2 bleaching techniques that are totally chlorine-free. This is to meet customers’ demands and also reduce the addition of chemicals.

♦ Softness Bamboo tissue is softer than its wood counterpart. It doesn’t cause allergies, and dust, making it ideal for infants, rhinitis patients, and sensitive people generally.

♦ Strength Bamboo fiber is inherently strong and doesn’t need any chemicals for added strength. Unlike other paper types, bamboo tissue paper doesn’t slag or drop particles when in use.

♦ Embossing and Odor Generally bamboo pulp paper doesn’t need to add smell. But manufacturers can easily meet customers’ needs if there is a call for embossing.

♦ Packaging Bamboo pulp paper in most parts of the world is packaged in environmentally friendly packaging. These include Kraft paper bags, degradable plastics, and other environmentally friendly cartons. With this, the environmental pollution caused by plastic is greatly reduced.

♦ Strong Water Absorption Research has shown bamboo as number one amongst five all-natural fibers in terms of moisture absorption and air permeability. This is all thanks to the composition and structure of the fiber.

♦ Antibacterial and Bacteriostatic Bamboo fiber has a unique substance called “Bamboo Quinone”. This is the latest report on bamboo toilet paper from Newland Bamboo in October (2020). The inhibition rate of Escherichia coli and Staphylococcus aureus was 90% and 99% respectively.

♦ 100% Biodegradability While it’s true wood tissue paper can be recycled, it isn’t as dependable as bamboo tissue paper. Bamboo fiber is biodegradable and naturally disintegrates with time.

3. Transportation

Consumers spend more on bamboo transportation as most bamboo pulp paper mills are located in countries like India, Bangladesh, China, Thailand, and so on.

4. Price

In all aspects of raw material processing and production, bamboo toilet paper manufacturers try to reduce harm to the environment and human health. Therefore, the cost is higher than that of wood toilet paper. But bamboo tissue has a considerable prospect in the market. For consumers, choosing bamboo toilet paper is more environmentally friendly and healthier; for brands, choosing bamboo toilet paper promotes the development of environmental protection and creates economic benefits at the same time.

Recycled Toilet Paper

1. Raw Materials

The raw materials used for recycled paper are of two types; pre-consumption and post-consumption. The pre-consumption of raw materials is some of the waste of the paper production process. These include wood particles, sawdust, offcuts of wood, and even papers manufactured for a long term without being used.

The post-consumption raw materials refer to used papers such as magazines, newspapers, and books among others. Recycled paper is preferred to wood pulp paper because it reduces the felling of trees and at the same time meets the demands of consumers.

It also reduces the environmental pollution caused during the pulping process. Similarly, there is a marked reduction in the discharge of wastewater compared to virgin papermaking. This makes it a very close option to bamboo pulp paper in terms of environmental friendliness.

The notable downside of recycled paper raw material is the reduction in the quality after being recycled multiple times. Most papers can withstand recycling 4 to 6 times before the fibers become weak and short. Also, it contains and involves the use of chemicals – especially BPA – and a notable amount of energy to mix the raw materials. Because a lot of recycled paper comes from magazines and newspapers-both of which contain high levels of BPA.

2. Features of Recycled Tissue Paper

♦ Color Due to the recovery of raw materials with ink and dirt. Recycled paper may use chemicals used for dyeing or bleaching during processing. This is inevitable. A common chemical used is bisphenol-A (BPA) which causes heart diseases, fertility problems, and some other health issues.

♦Softness and Strength Recycled paper ranks lowest in terms of tenderness and strength when compared with bamboo and wood pulp paper. This prompts some manufacturers to add chemical treatment steps to get the needed strength and softness. Some manufacturers even go as far as adding fluorescent brighteners – a chemical banned by the state – to get the required level of the indicator.

♦ Embossing and Odor Manufacturers can easily emboss and add odor during the manufacturing process as required by customers.

♦ Packaging Recycled paper is undoubtedly environmentally friendly. But Recycled tissue paper usually comes in plastic packaging. This adds to plastic pollution in the environment.

3. Transportation

Just like wood pulp paper, recycled paper has proximity to its advantage. Hence, buyers only pay less transportation cost.

4. Price

Recycled paper is the most cost-effective amongst the three toilet paper types. This is due to the low price of raw materials and the lower cost in the production process.

How do we choose?

Considering the paper types from the environmental protection angle, bamboo and recycled pulp papers are the go-to options. Amongst these two options, bamboo is the one with better quality and more health benefits.

One of the major advantages of using bamboo instead of trees for papermaking is the marked reduction in deforestation. It is proven that approximately 330 million trees are cut down every year. This fact added to the long growth period of trees does more harm to the ecosystem than benefit.

Bamboo, on the other hand, has high renewability and yield, making it the perfect substitute for trees in the papermaking industry. What makes this change is even paramount is the rapidly increasing demand for toilet paper. And this demand comes with harmful climate changes.

Therefore, we know we can effectively contribute to the reduction of deforestation by adopting sustainable raw materials. So, why don’t we just be amongst the growing faces of this change? 100% natural bamboo pulp paper is undoubtedly the planet saver we crave.

While we know that consumers can use their purchasing power to help trigger this change, the manufacturers should be at the forefront of it. The effectiveness of this change can only be achieved if manufacturers and brands take up the responsibility to sensitize consumers. Creating environmental awareness and encouraging consumers to take up more sustainable consumption habits.

Newland Bamboo is a committed firm driven by a shareholder with over 20 years of tissue paper production experience. We are fully passionate and dedicated to producing 100% eco-friendly and healthy bamboo tissue papers to continuously benefit you and our planet at large. Lastly, being a household bamboo toilet paper manufacturer, we maximize our wide range of resources towards satisfying local needs and export customized and customizable products to private label brands and other manufacturers worldwide.

If you have more opinions or want to cooperate with us, please feel free to contact us.

FAQ:

-

What are the differences between wood, recycled, and bamboo toilet paper?

Wood toilet paper uses wood pulp, which requires extensive energy, water, and chemicals, contributing to deforestation. Recycled paper reduces tree cutting but often contains chemicals like BPA and loses strength after several recycling cycles. Bamboo toilet paper, made from fast-growing bamboo, is more sustainable, free from harmful chemicals, and is biodegradable.

-

Why is bamboo toilet paper better for the environment?

Bamboo grows rapidly, needs minimal water, and does not require harmful pesticides. It regenerates in a few months, reducing the need for tree cutting, which helps preserve forests. Additionally, bamboo paper is biodegradable and doesn’t release harmful chemicals into the environment, unlike some wood pulp and recycled papers.

-

Is bamboo toilet paper safe for septic systems?

Yes, bamboo toilet paper is septic-safe. It is biodegradable, breaks down quickly, and does not contain harsh chemicals or additives, ensuring it won’t damage your septic system.

-

How does the price of bamboo toilet paper compare to wood or recycled paper?

Bamboo toilet paper is generally more expensive than wood or recycled toilet paper due to the cost of sustainable sourcing and production methods. However, its superior quality, strength, and environmental benefits make it a worthwhile investment in the long term.

-

Can bamboo toilet paper be customized for businesses?

Yes, bamboo toilet paper can be customized for private labels and businesses. Companies like Newland Bamboo offer customization options to cater to specific brand needs while ensuring eco-friendly production.

-

Is bamboo toilet paper soft and strong?

Yes, bamboo toilet paper is naturally softer and stronger than many other types of paper. It’s hypoallergenic, antibacterial, and gentle on the skin, making it ideal for sensitive users.